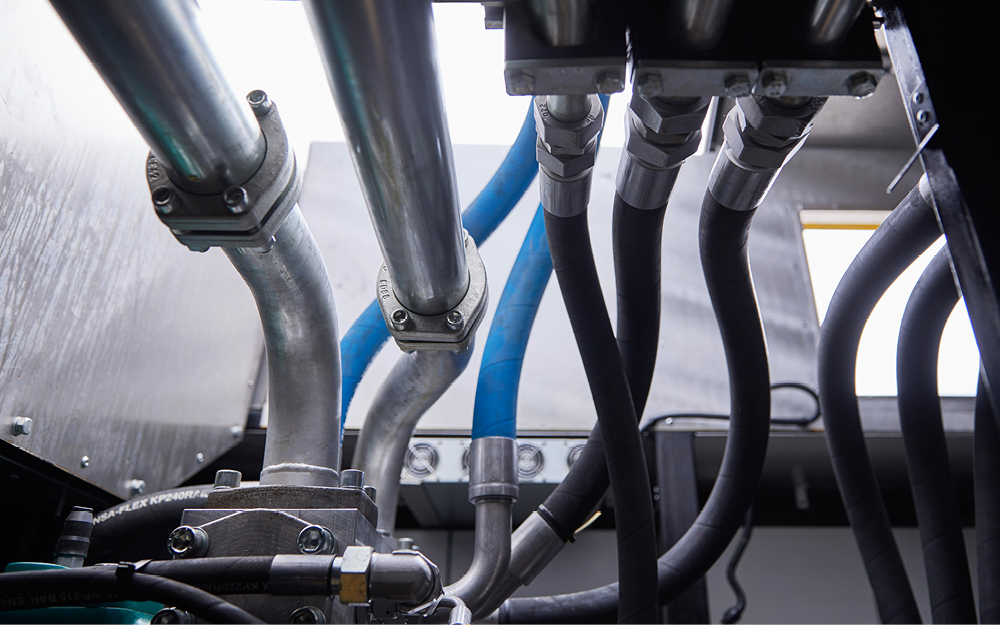

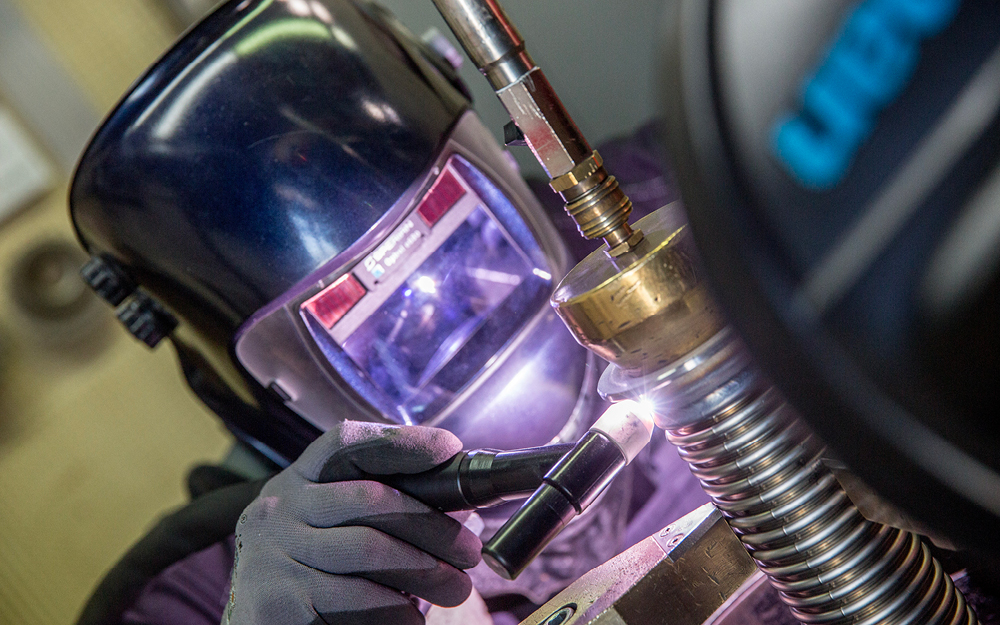

After determining the cut dimension, we cut the hydraulic hose to the correct length using special hose cutting machines. We then skive the hose to obtain the required skive length for the chosen joining method and check the result for correct nipple constriction.

Türkçe

Türkçe