Contamination with solids

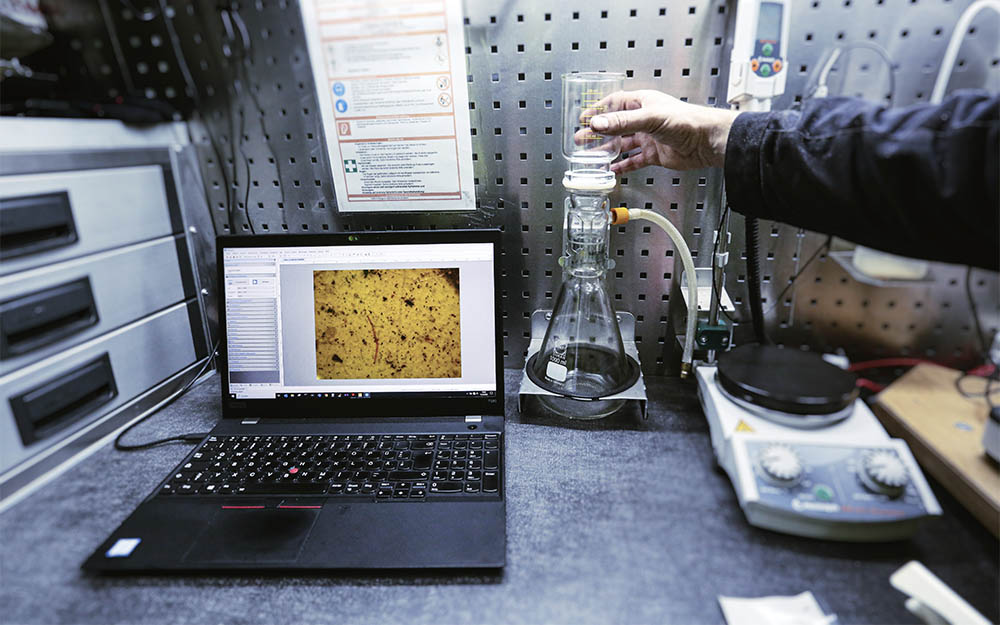

Contamination of the hydraulic oil with solids such as dust or metal or seal particles is one of the most frequent causes of damage. The source of the particles may be unfiltered fresh oil, inadequate filter design, an inadequately filled tank, wear of components or the ingress of dirt particles during assembly. The first step in rectifying this problem is to examine the whole system, including the use of on-site particle counters if necessary. By doing this, you can be absolutely sure of the cause of the damage and take exactly the measures required to prevent the ingress of dirt, such as installing filter systems.

Türkçe

Türkçe