Oil Filtering and Cleaning

Oil Filtration Ensures Clean Fluid and Efficient Processes

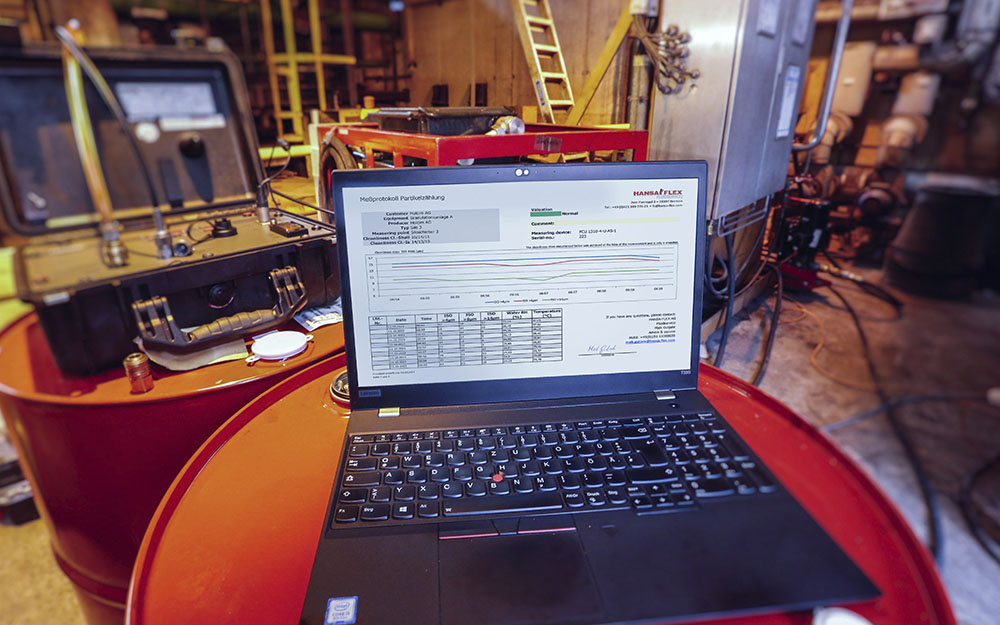

Solid and liquid contaminants cause wear, increase abrasion and promote corrosion. Regular oil filtration ensures your production processes run smoothly and helps to prevent damage to equipment, systems and machinery. The fluid experts from HANSA-FLEX carry out professional oil cleaning to achieve the desired level of cleanliness and find the perfect filter solution for your hydraulic system.

Türkçe

Türkçe