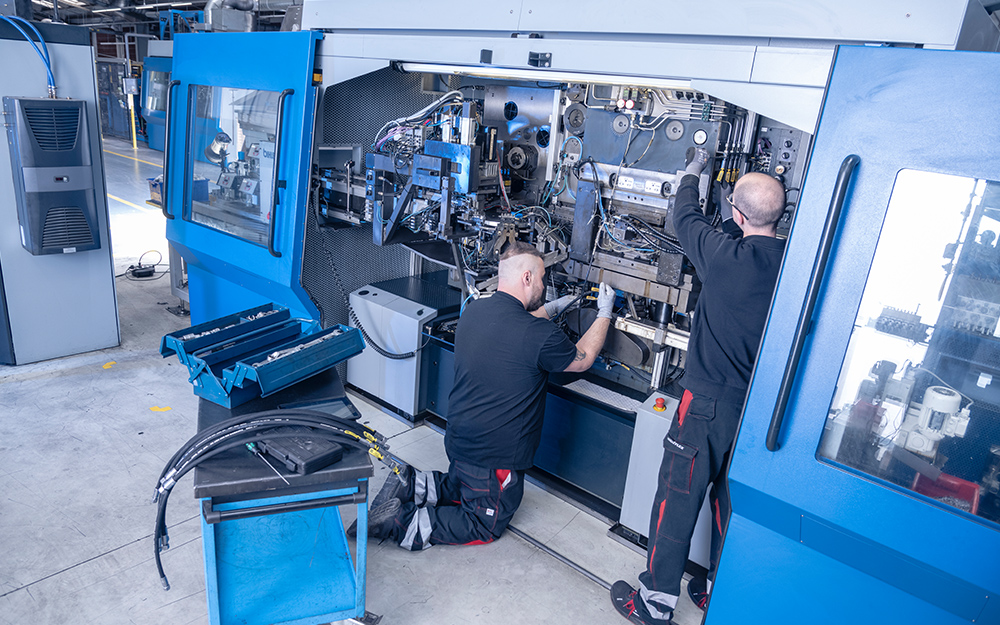

Inspection of hydraulic hose lines

We carry out the legally prescribed checks of your hydraulic hose lines in accordance with BetrSichV / DGUV for you and ensure the legally compliant documentation of the results. The inspections are carried out directly for you on site by officially authorised persons for the inspection of hydraulic line equipment. Each inspection can be booked as an individual service or as part of our hose management package within our 360° hose management service.

Türkçe

Türkçe